5S Audits: Enhancing Efficiency and Safety in Industrial Workplaces

July 19, 2022

From Lockbox to Lockout Station: Elevating Workplace Safety at EZSecur

July 19, 2022

5S Audits: Enhancing Efficiency and Safety in Industrial Workplaces

July 19, 2022

From Lockbox to Lockout Station: Elevating Workplace Safety at EZSecur

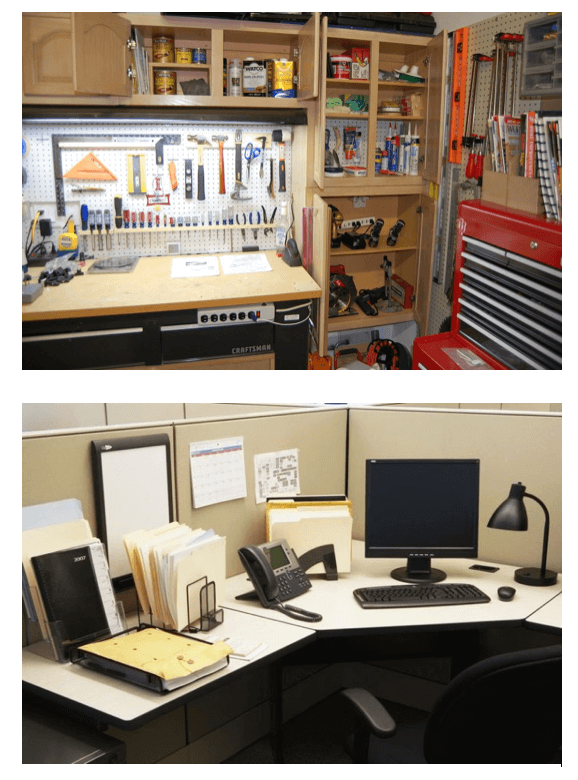

July 19, 2022In today’s fast-paced industrial environment, maintaining an efficient and organized workspace is essential for productivity and safety. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving this. By implementing 5S, industrial teams can create a streamlined, harmonious workspace that not only reduces clutter but also enhances workflow and reduces stress. Here are five actionable tips to help you integrate 5S principles into your workplace effectively.

1. Begin with a Clean Slate: Sort and Purge Unnecessary Items

Start with a focused decluttering process. Target specific areas within your facility and remove items that don’t serve a clear purpose. This focused purging clears the path for a more organized layout and reduces time wasted searching for essential items.

2. Use Color-Coding and Labels for Quick Access

Visual management is key in an industrial setting. Create an intuitive system of labels and colors for shelves, bins, drawers, and workstations. Mark pathways and storage areas clearly, so employees can easily navigate the space and return items to their designated places, promoting efficiency.

3. Prioritize Accessibility for Ergonomic Efficiency

Ensure frequently used tools and materials are stored in accessible locations close to workstations. Consider using shadow boards and ergonomic storage solutions that allow quick retrieval and reduce the risk of physical strain, keeping essential tools within arm’s reach.

4. Structure Your Day: Plan and Prioritize Tasks

Time management is crucial to minimizing downtime. Establish clear task schedules and assign specific time blocks for different activities to keep everyone focused and organized. This structured approach minimizes interruptions, ensuring high-priority tasks receive the attention they deserve.

5. End Each Day with a Quick Organization Session

Develop a daily habit of tidying up at the end of each shift. Spending just a few minutes resetting the workspace helps employees start fresh the next day. A clean, organized space not only boosts productivity but also fosters mental clarity and motivation.

Adopting 5S is about more than just a cleaner workspace; it’s about creating a culture of efficiency and continuous improvement. By following these practical steps, you’ll create a safer, more productive environment for your team. For customized safety solutions and expert guidance on industrial signage and organization, turn to EZSecur. Learn more at www.ezsecur.com.