Enhancing Remote Site Safety: Énergir and EZSecur’s Innovative Lockout Solutions

July 19, 2022

Enhanced Lockout Solutions Drive Safety and Efficiency at Montreal’s Termont Port

July 19, 2022

Enhancing Remote Site Safety: Énergir and EZSecur’s Innovative Lockout Solutions

July 19, 2022

Enhanced Lockout Solutions Drive Safety and Efficiency at Montreal’s Termont Port

July 19, 2022Termont’s journey to elevate workplace safety through the development of a groundbreaking mobile lockout box represents a major step forward in industrial safety practices. In close collaboration with EZSecur, this initiative reflects a shared commitment to continuous improvement and stringent operational safety. The outcome—a secure, unbreakable, and mobile lockout box prototype—illustrates a blend of engineering expertise and a proactive safety-first culture in the industrial sector.

Building Resilience: From Prototype to Practical Safety Tool

The foundation of Termont’s safety enhancement project was the development of a robust mobile lockout box prototype. Engineered for durability and operator convenience, the prototype addresses industrial demands for a safety tool that’s both tamper-proof and user-friendly. The primary challenge was achieving an unbreakable design that remains practical for regular use in demanding environments.

Synergy in Safety: EZSecur’s Strategic Partnership

A key factor in Termont’s success was the strategic partnership with EZSecur, which provided technical insights and innovative solutions essential to the lockout box’s design. EZSecur’s expertise enabled Termont to move from concept to a refined product, ensuring the box met stringent operational and safety requirements.

Meeting Real-World Needs: Enhanced Features for Daily Operations

As the lockout box evolved, Termont identified the need for additional functional features. One key addition was a dedicated compartment for critical safety documents, such as procedure manuals and lock cards. This enhancement ensures that essential safety information is readily accessible, helping operators adhere to safety protocols without disruption.

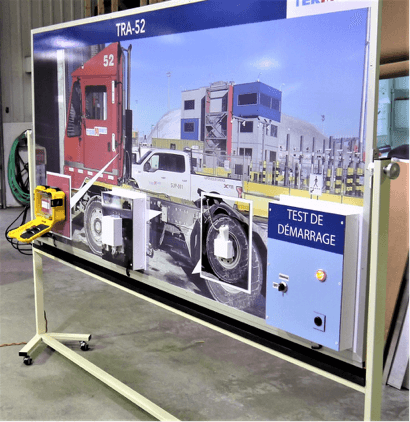

Seamless Training with Lockout Simulation

Understanding the importance of hands-on training, Termont integrated a lockout simulator to equip operators with essential lockout/tagout skills without halting equipment operations. EZSecur supported this effort by creating a lockout procedures simulator board that mirrors Termont’s specific mobile equipment. This innovation enables efficient and practical safety training, reinforcing procedural accuracy and operator confidence.

Setting New Standards in Industrial Safety

The successful implementation of mobile lockout boxes at Termont sets a high standard in industrial safety innovation. This achievement highlights the impact of collaborative partnerships, adaptability, and proactive safety strategies within the industry. Termont and EZSecur’s work serves as an inspiring example for organizations committed to safer work environments.

For customized industrial safety solutions, signage, and expert guidance, contact EZSecur. Learn more at www.ezsecur.com.