Proactive Safety Strategies: Strengthening Workplace Protection in Industrial Settings

July 18, 2022

Boosting Safety in Industrial Workspaces: A Practical Guide to Pedestrian Walkway Markings

July 18, 2022

Proactive Safety Strategies: Strengthening Workplace Protection in Industrial Settings

July 18, 2022

Boosting Safety in Industrial Workspaces: A Practical Guide to Pedestrian Walkway Markings

July 18, 2022Forklift accidents are a major cause of workplace injuries and fatalities, particularly in industrial settings. According to the Canadian Centre for Occupational Health and Safety (CCOHS), work-related deaths are on the rise, with many linked to forklift incidents. Key contributors include excessive speed, improper load handling, and poor communication. Implementing enhanced safety measures and thorough training programs is essential for reducing risks and ensuring a safer workplace.

Understanding Forklift Dynamics

Weight and Speed Hazards

Forklifts can weigh up to 9,000 pounds and reach speeds of 18 mph, making them extremely dangerous if not operated carefully. Their sheer mass and momentum require strict safety protocols, such as designated operational zones and controlled speed limits, to minimize hazards.

Braking and Maneuverability Challenges

Unlike standard vehicles, forklifts have front brakes and an uneven weight distribution, making braking and handling more complex. Operators must be trained to navigate these challenges, understanding how to control their speed and recognize potential hazards in the work environment.

Addressing Steering and Visibility Issues

Rear-Wheel Steering Risks

Forklifts use rear-wheel steering, which causes the back end to swing outward during turns—significantly increasing the risk of tip-overs and collisions. Operators must be trained to anticipate these movements and adjust their steering accordingly.

Limited Visibility

Front-mounted loads often obstruct an operator’s line of sight, increasing the chances of accidents. Solutions such as installing mirrors, using forklift-mounted cameras, and optimizing load placement can greatly improve visibility and reduce collision risks.

Proactive Measures to Reduce Forklift Accidents

Pedestrian Safety Measures

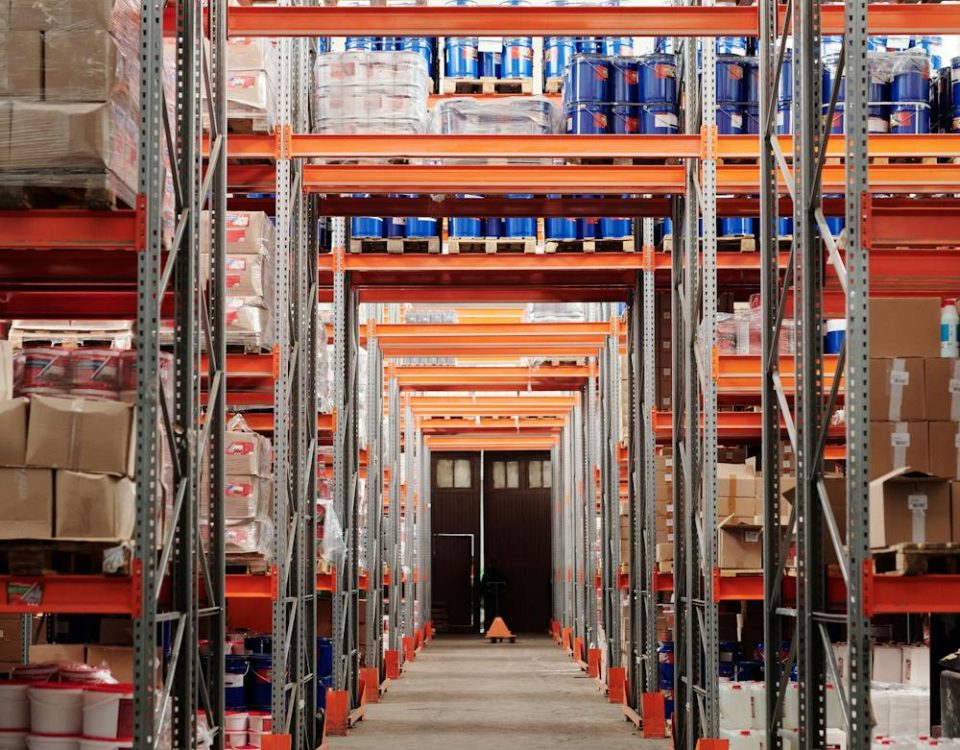

Separating forklift traffic from pedestrian pathways is one of the most effective ways to prevent accidents. Installing guardrails, floor markings, and designated walkways helps create clear boundaries and improves overall workplace safety.

Enhanced Lighting

Poor visibility is a leading cause of workplace accidents. Upgrading lighting systems, especially in high-traffic areas, improves visibility for both operators and pedestrians, reducing navigation errors.

Optimized Load Handling

Restricting load sizes and ensuring proper weight distribution minimizes the risk of tip-overs. Operators should be trained to assess load stability and secure cargo before transport.

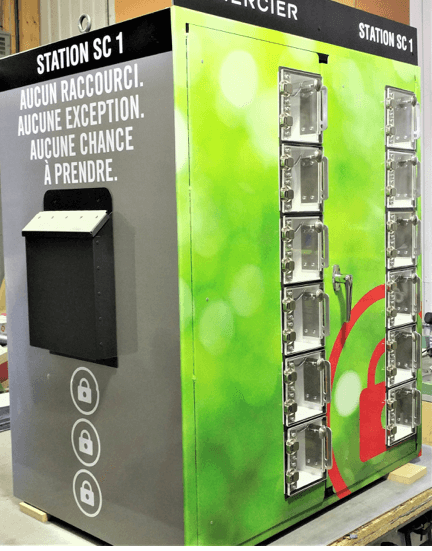

Collision Prevention Technology

Modern safety solutions, such as alarms, strobe lights, and proximity sensors, can alert both operators and pedestrians to potential hazards, significantly reducing the likelihood of accidents.

Creating a Safer Workplace

Forklifts are essential for industrial operations, but their risks must be proactively managed. By investing in comprehensive operator training, improving workplace layouts, and adopting advanced safety technologies, businesses can significantly reduce forklift-related accidents.

At EZSecur, we specialize in industrial safety solutions, from customized signage to cutting-edge workplace safety products. Let us help you create a safer, more efficient environment. Learn more at www.ezsecur.com.