Optimize Your Industrial Workplace with 5S Methodology

July 18, 2022

Avoiding 5S Pitfalls: Key Strategies for Lasting Success

July 18, 2022

Optimize Your Industrial Workplace with 5S Methodology

July 18, 2022

Avoiding 5S Pitfalls: Key Strategies for Lasting Success

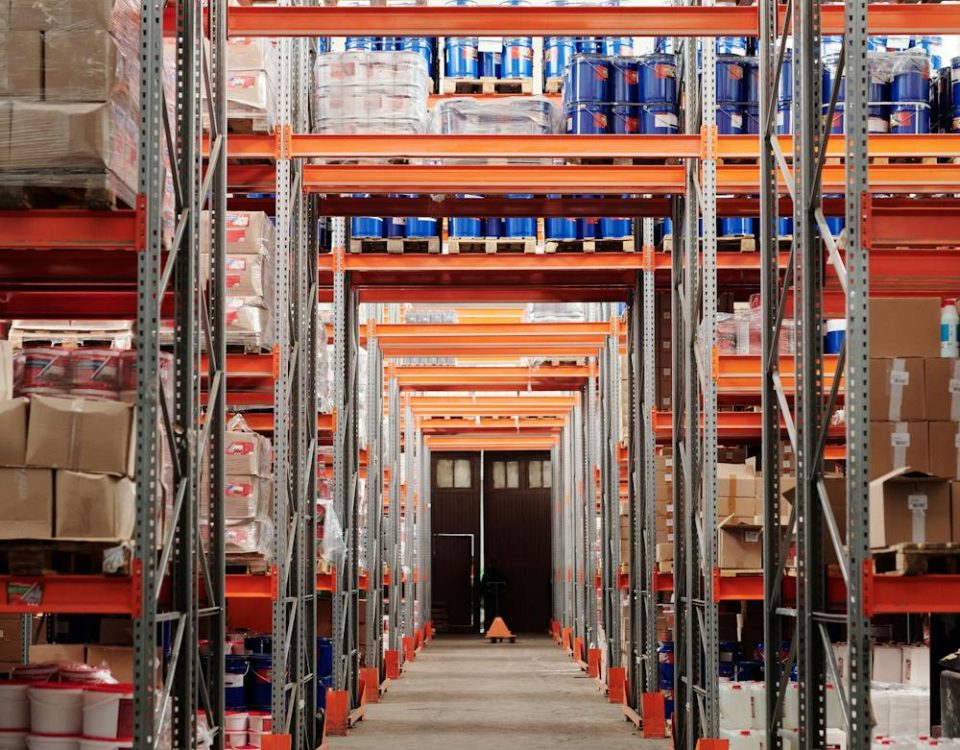

July 18, 2022In today’s fast-paced manufacturing environment, efficiency, organization, and safety are more critical than ever. The 5S methodology—built on five foundational Japanese principles: Sort, Set in Order, Shine, Standardize, and Sustain—provides a structured approach to creating a well-organized, high-performing workspace. Integrated with lean manufacturing practices, 5S enhances systems like just-in-time (JIT), cellular manufacturing, total quality management (TQM), and Six Sigma, driving continuous improvement across operations.

Breaking Down the 5S Methodology

1. Sort: Eliminating the Unnecessary

The first step focuses on removing clutter by discarding tools, materials, and equipment that don’t serve a purpose. This not only frees up space but also reduces hazards and enhances efficiency.

2. Set in Order: Organizing for Productivity

Every tool and material should have a designated place. A well-organized workspace minimizes search time, streamlining processes and boosting productivity.

3. Shine: Prioritizing Cleanliness

Routine cleaning prevents dirt buildup, reduces equipment failures, and improves workplace safety by eliminating potential hazards like spills or debris.

4. Standardize: Maintaining Consistency

Establishing clear, repeatable procedures ensures that the first three steps are ingrained in daily operations, fostering long-term success.

5. Sustain: Creating a Culture of Continuous Improvement

Sustaining 5S requires commitment from leadership and employees alike. By integrating regular audits and training, organizations can ensure 5S remains a core aspect of operations.

The 5S Advantage: Enhancing Safety and Productivity

Implementing 5S leads to a safer, more efficient work environment. By maintaining order and cleanliness, organizations can:

✅ Reduce workplace accidents by eliminating hazards.

✅ Minimize downtime caused by misplaced tools or inefficient layouts.

✅ Support compliance with safety regulations and lean principles.

✅ Increase employee engagement by fostering a culture of workplace pride and accountability.

5S in Action: A Real-World Impact

Consider a manufacturing plant where technicians frequently struggle to find tools during machine changeovers. By implementing 5S principles, tools are strategically stored and labeled, ensuring quick access. The result? Reduced downtime, improved workflow, and a safer workplace.

The beauty of 5S is its adaptability—whether in large-scale production or small operations, this methodology drives efficiency and enhances safety across industries.

Transform Your Workplace with 5S

5S isn’t just about keeping things tidy—it’s a key driver of operational excellence. By reducing waste, improving safety, and boosting productivity, 5S helps manufacturers create streamlined, efficient, and compliant workspaces.

At EZSecur, we support your 5S journey with industrial safety products, expert guidance, and custom signage solutions to reinforce workplace organization.

Ready to optimize your facility? Visit www.ezsecur.com to learn more