Thriving Amidst Disruption: Resilience Strategies for Manufacturers

July 15, 2022

Thriving in a Dynamic Market: The Power of Flexible Capacity

July 15, 2022

Thriving Amidst Disruption: Resilience Strategies for Manufacturers

July 15, 2022

Thriving in a Dynamic Market: The Power of Flexible Capacity

July 15, 2022The manufacturing sector is undergoing a remarkable transformation, fueled by technological innovations that redefine operational capabilities. At the forefront of this revolution is the Internet of Things (IoT), an advanced network of interconnected devices driving improvements in efficiency, speed, and quality. This article delves into the transformative role of IoT in manufacturing, with a focus on its impact on safety and operational performance.

IoT’s Role in Modern Manufacturing

IoT connects devices, sensors, and systems to enable seamless data collection and communication within industrial environments. These sensors monitor crucial variables like energy consumption, temperature, machinery usage, and logistics. When paired with artificial intelligence (AI) and machine learning (ML), IoT translates raw data into actionable insights. These technologies detect anomalies, optimize workflows, and empower manufacturers to enhance both safety and efficiency.

Boosting Production Efficiency with IoT

The real-time monitoring capabilities of IoT devices are revolutionizing production processes. By continuously tracking machine performance, energy usage, and daily operations, manufacturers can make informed decisions and address potential issues before they escalate. This proactive approach reduces downtime, enhances efficiency, and improves safety.

For instance, IoT sensors can identify when machinery is overheating or consuming excessive energy. Early detection enables preemptive maintenance, reducing the risk of hazardous failures and costly disruptions.

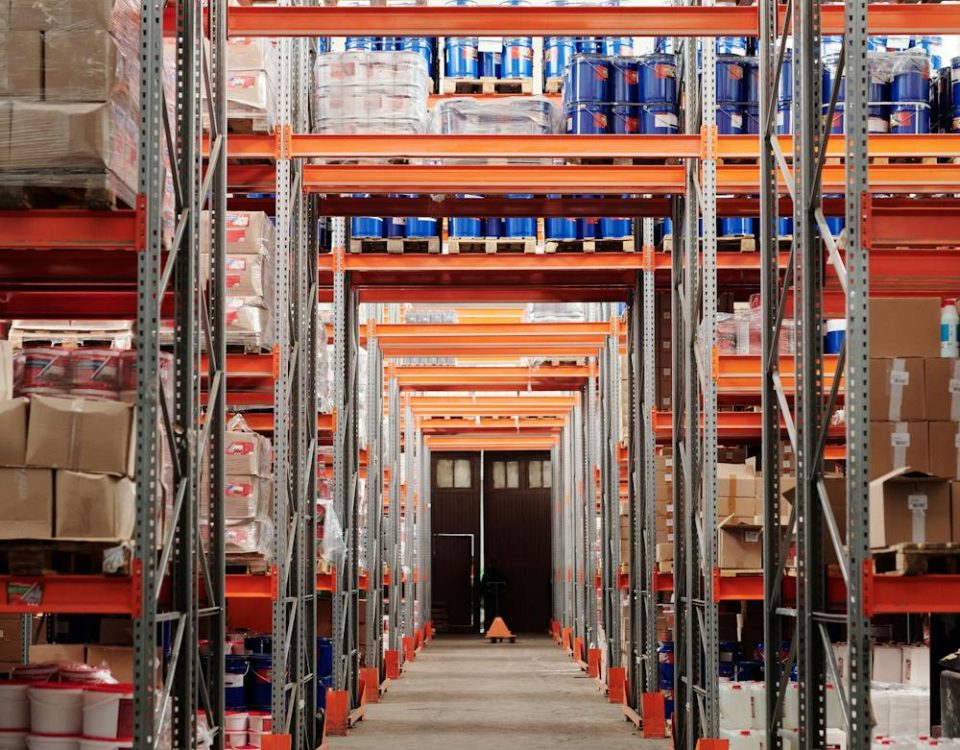

IoT Beyond the Factory Floor

The benefits of IoT extend beyond the confines of production facilities, reaching into supply chain management. IoT provides comprehensive visibility across the supply chain, from raw material acquisition to product delivery.

With IoT-enabled tracking systems, manufacturers gain real-time updates on product location, condition, and transportation status. These insights enhance production planning, reduce delays, and improve customer satisfaction by ensuring timely and accurate deliveries.

Addressing IoT Implementation Challenges

Despite its immense potential, implementing IoT in manufacturing comes with challenges. Establishing a robust IoT infrastructure involves significant initial investments, although declining sensor costs are making adoption more accessible.

One critical hurdle is overcoming data silos—systems that operate independently and hinder seamless communication. Integrating IoT with technologies like blockchain can resolve interoperability issues while enhancing data security.

Speaking of security, as more devices connect to industrial networks, the risk of cyberattacks increases. Manufacturers must adopt stringent cybersecurity measures and policies to safeguard their IoT ecosystems.

The Future of IoT in Manufacturing

The integration of IoT is reshaping manufacturing into a smarter, safer, and more efficient industry. While challenges like costs and cybersecurity persist, the potential benefits far outweigh these obstacles.

For expert guidance on industrial safety products, signage, and workplace safety solutions, trust EZSecur. Explore our offerings at www.ezsecur.com and discover how we can support your journey toward safer and smarter operations.